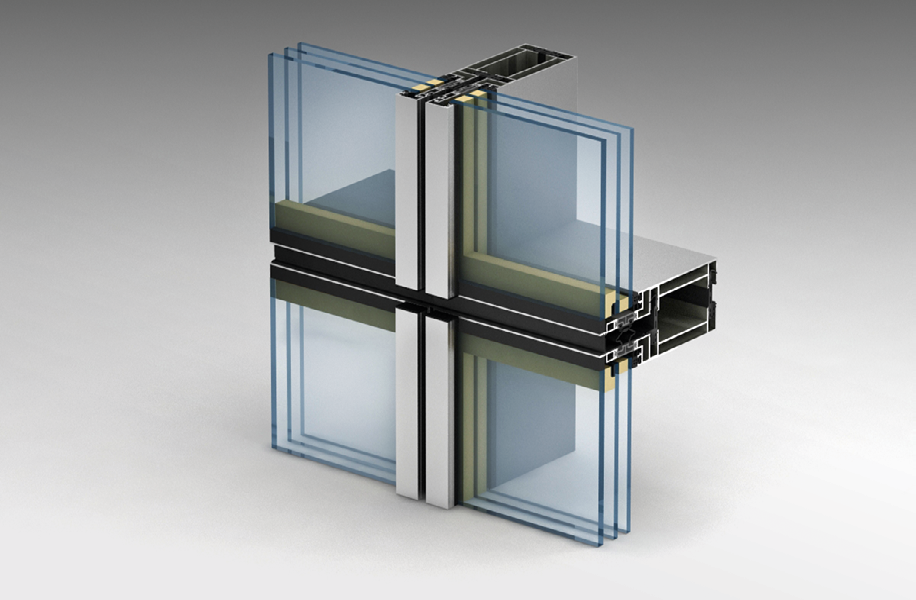

ALT EF65 VL «Vertical line» unitized curtain wall

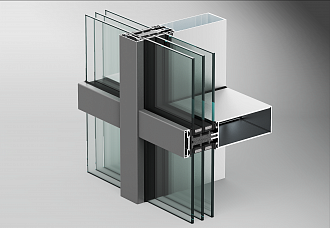

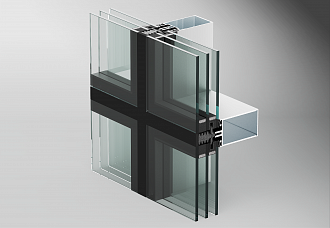

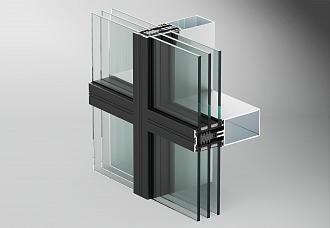

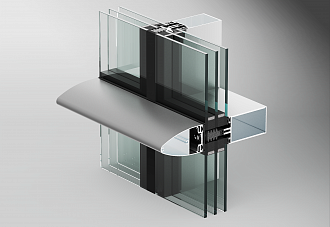

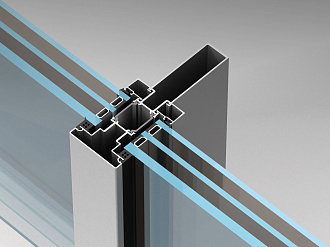

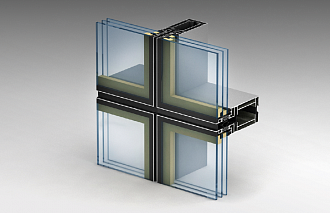

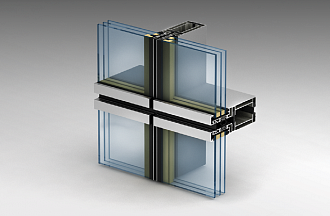

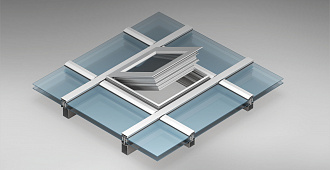

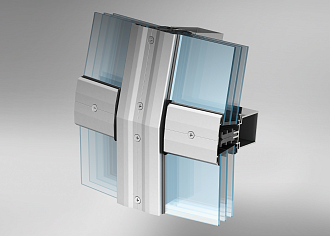

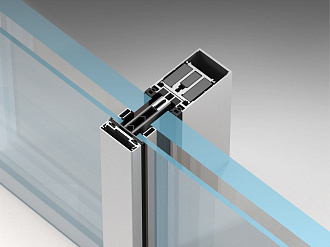

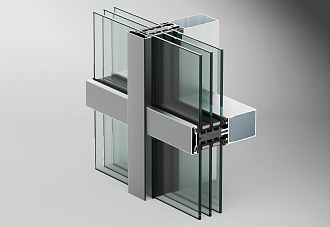

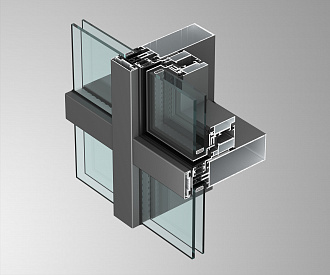

ALT EF65VL is a variant of modular EF65 facade system in which the vertical direction of the infill unit fixation is visually distinguished from the outside (by means of glass beads). In this case, the horizontal direction is a variant of structural glazing.

In order to achieve a more expressive appearance, instead of glass beads, it is allowed to use various sub-object decorative profiles, which make buildings look more extensional in vertical direction.

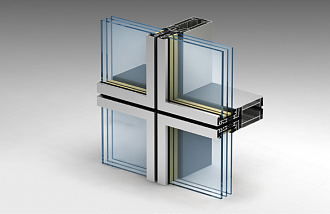

This system provides broad opportunities for architectural design while maintaining all the necessary indicators of tightness, strength and reliability, which are so necessary for high-rise buildings.

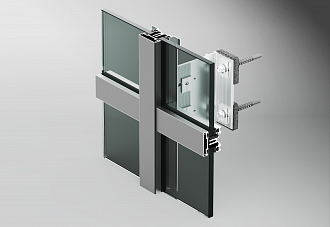

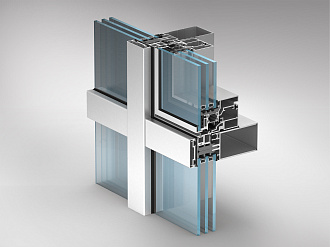

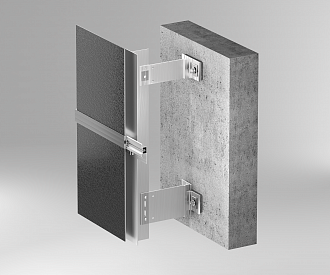

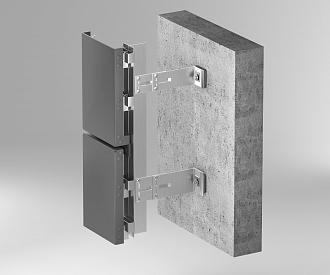

The design features of the element (modular) facade determine the high speed of work on the construction site, since all elements are completely pre-assembled in the workshop. At the same time, due to the small visible dimensions of the profiles (only 65 mm), high performance and technological efficiency are combined with architectural aesthetics.

ALT EF65 VL Façade system meets the highest requirements for tightness, air permeability and resistance to wind loads. The system is available with different levels of thermal insulation and the application of different types of glazing.

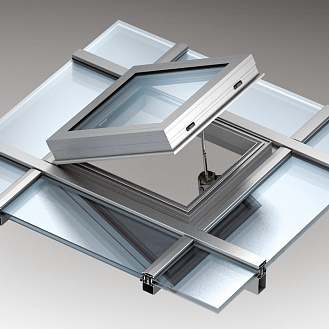

Types of integrated units:

- ALT W62 and W72 window and door systems;

- integrated facade windows of various types (top-hung, parallel-sliding windows, «hidden sash» windows).

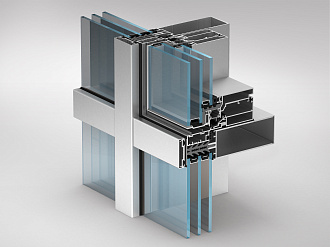

- standardization of elements at the stage of design;

- high assembly quality, precise control of manufacturing process, final quality inspection;

- on-site mounting with fewer work operations, which significantly reduces the «human factor» effect (faulty goods);

- period of construction doesn’t depend on weather conditions, as the products are manufactured in the workshop;

- a floor-by-floor installation method is used, therefore, due to concealed thermal insulation jig finishing works can be carried out at the earlier stage;

- mounting can be carried out at low temperatures without significant changes in the technological process.

1. POWDER COATING

- any RAL-colour according to Qualicoat;

- exclusive collections (Futura, Precis, Anodic);

- variety of surface types (glossy, matte, textured);

- innovative antimicrobial BIO-coating option.

2. ANODIZING

- conformance to Qualanod standard;

- 9 standard colours;

- possibility to choose different surface treatments (chemical etching, bead blasting, brushing).

3. WOOD-GRAIN EFFECT

- conformance to Qualicoat standard;

- 5 woodgrain options.