Production automation

All ALUTECH plants are equipped with high-tech production lines, automated warehouses and robotized production complexes.

All ALUTECH plants are equipped with high-tech production lines, automated warehouses and robotized production complexes.

Alutech Incorporated LLC, Minsk

Manufactures and markets shaped sections, components, accessories and control systems for roll-up doors. The plan includes the following equipment:

- aluminum and steel strip painting and cutting complex,

- cutting line for longitudinal cutting of painted strip master rolls to any size shaped sections,

- automated roll forming lines for production of rolled aluminum sections, protective ducts, moldings, and octagonal shafts.

The production facilities of the factory allow to paint up to 25 000 tons of aluminium strip or 70 000 tons of steel strip and to manufacture up to 150 million linear meters of roller profiles.

Alutech Doors Systems LLC, Minsk

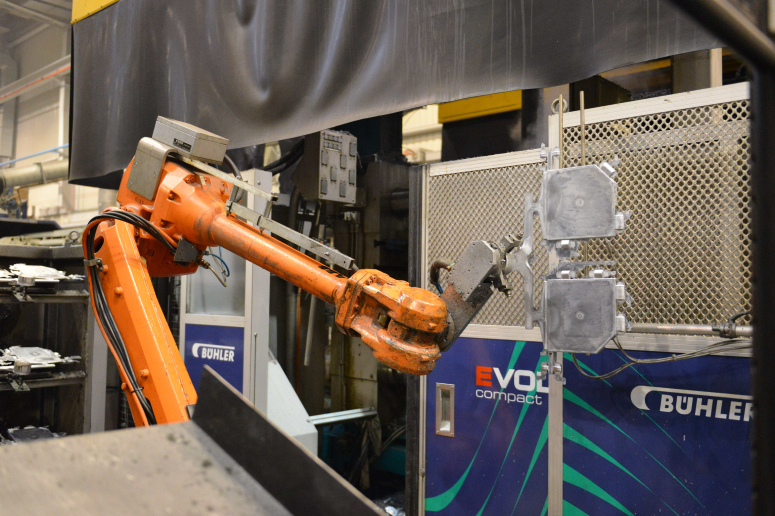

Specializes in manufacturing of sectional gates, sandwich panels and components, as well as pressure molded aluminum alloys products. The plant has:

- automated gate leaf manufacturing line,

- 2 automated sandwich panel manufacturing lines,

- steel strip cutting line,

- shaped section and sandwich panel powder coating line,

- casting complex for gate parts and components production,

- automated warehouse for sandwich panels.

The factory’s production facilities allow to manufacture over 240 000 doors in a year (500-600 products per day). Automatic warehouse capacity is 230 000 linear meters of sandwich panels.

AluminTechno JLLC, Minsk

The biggest in the CIS plant for manufacturing, powder painting and anodizing of aluminum shaped sections. The main components of AluminTechno production facility are:

- casting shop,

- 6 high-tech press lines,

- 2 powder painting lines,

- polymer coating line,

- shaped section anodizing complex.

The factory is able to produce over 55 000 tons of aluminium profiles every year.

Alutech-Sibir LLC, Novosibirsk

Alutech-Sibir is a modern manufacturing facility for roller shutter systems, sectional doors and entrance gates, which promptly supplies ALUTECH products to the Siberian, the Far Eastern and the Ural Federal Districts of Russia. The factory has its own equipment, such as:

- two automated lines for door leaf production,

- production sites for manufacturing track profiles for sectional doors,

- кcoating complex for sectional doors.

The production capacity of the factory is 28 000 doors per year.

Alutech LLC, Vsevolzhsk (Leningrad region)

The company has its own facility for full-cycle production of aluminium profile systems, in particular aluminium-wood windows — the new ALUTECH product.

The production facility includes the following units:

- production site,

- glazing installation section,

- packing section,

- storage facility.

Production capacity of the company is over 20 000 sq. m of finished products per year.